How To Clean A Clogged Nozzle.on An Ender 3

If yous ever had this event happen to yous where the impress head is moving and and then of a sudden rips the whole print off the bed, or if you've dealt with a chock-full nozzle at some indicate and didn't know how to properly unclog it, so stick effectually since I will cover how to solve both of these problems in this article.

So, without any further ado, allow'south become started with the simplest problem to fix!

Make clean the nozzle and heatblock using a brass castor

Molten filament tin adhere to the nozzle and fifty-fifty to the heatblock and this might cause the nozzle to stick to the print, ripping it off the build surface while moving.

This issue isn't that common when printing with PLA or ABS, merely PETG, for instance, has a different viscosity when melted and it tends to stick to the nozzle & heatblock a lot easier, causing a filament hulk over time that can disassemble the print from the build surface.

Here's how to clean the nozzle and the heatblock:

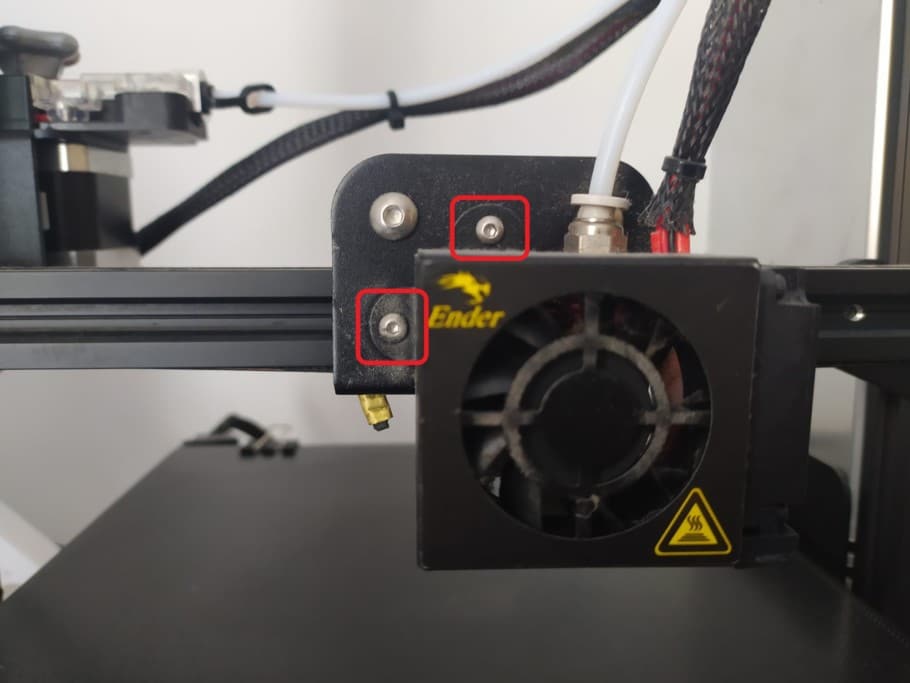

- Remove the fan shroud by removing the two screws.

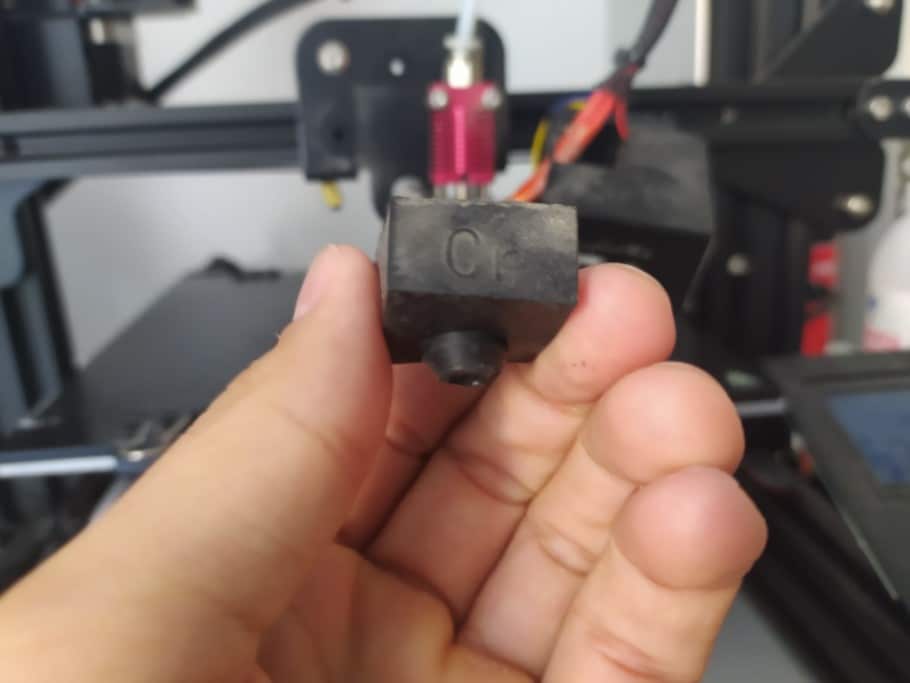

- Remove the silicon kicking on the heatblock (if there is any).

- Estrus upward the nozzle to the plastic'south required temperature (200°C for PLA).

- Using a brass brush remove all of the filament on the heatblock and nozzle.

- Let everything cool down and reinstall the fan shroud.

To preclude this outcome from happening also frequently, I'd recommend installing a silicon boot on your printer. Most printers already come up with one pre-installed, but if it didn't, then simply get one and install information technology yourself after thoroughly cleaning the hotend first.

The silicon boot will prevent the filament from sticking to the nozzle & heatblock and yous won't need to clean information technology every bit often.

Clogged nozzle: How does it happen?

Clogs are a very real issue that can happen to any 3D printer and that can cause havoc to your printer, ruining a print and even forcing you to sometimes having to detach the entire hotend to make clean it.

The main reasons for a nozzle getting clogged are;

- Heat Creep: When the heat travels further upwardly the hotend than it should and melts the filament where it shouldn't be melted, slowly adhering to the walls and tightening the gap where the filament is.

- Nozzle to close to the bed: This doesn't allow for proper filament flow and may cause "retrograde extrusion" (when the filament goes back up the nozzle), causing clogs.

- Too low of a printing temperature: If the temperature of your hot terminate is too low, your print material will not melt correctly. This tin cause the material to begin to adhere to the inside surface of the nozzle which will also increase the pressure inside the impress head, causing the extruder to have to push harder to movement the filament (until it can no longer feed the filament into the head).

- Grit Buildup: Dust that makes information technology inside the hotend may burn and adhere to the sides of the nozzle in the form of carbon, which will narrow the width of the nozzle'southward opening over time causing it to clog or to under-extrude.

- Poor Quality filament: Not all filaments are made following the aforementioned strict quality guidelines, and some may have a college tolerance (diameter throughout the entire spool) than others, or they might come with some contaminants that burn in the nozzle and cause it to clog over time.

Allow's take a quick look at how to deal with clogs as well as the necessary measures you need to take to forestall them from happening in the showtime place.

How to unclog a 3D Printer nozzle (shown on Ender 3)

Even though I'g going to exist showing how to do this on an Ender 3, yous tin can certainly follow the exact same steps for any other printer out there since it's pretty much the identical procedure.

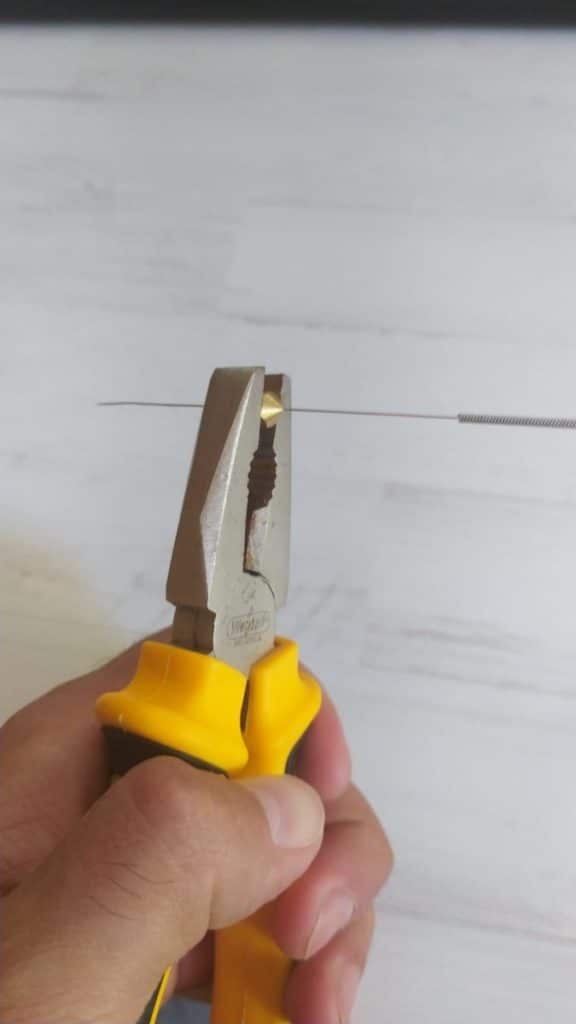

Unclog the nozzle using the included 0.4mm needle

All printers come with a needle that is used to unclog the nozzle, only if yours doesn't then you lot tin can get one here.

Here's how to unclog the nozzle using a needle:

- Preheat the printer to the filament'south melting temperature (200°C for PLA, 230°C for PETG and ABS, etc.).

- Insert the needle through the hole in the nozzle and push the filament upwards, so pull the needle out (repeat multiple times).

- Extrude some filament to bank check if it'due south flowing correctly.

- Repeat the process if necessary.

More often than not, this should solve the issue since pushing the clog upward will forcefulness information technology to exist melted. Likewise, if in that location'due south any dirt or grit that is causing the clog, pushing information technology may break information technology into smaller pieces that can and then be extruded with the filament through the nozzle'due south opening.

Perform a common cold Pull (Diminutive Pull)

Doing a common cold pull is but what it sounds like: You remove the filament from the printer without properly heating the nozzle, causing the cold filament to take whatever material there is that is blocking the nozzle with it.

Here's how to perform a common cold pull:

- Heat the nozzle to 220°C (If yous but printed with PLA).

- Insert a piece of white or calorie-free-colored Abs, Nylon, or whatever strong filament with good thermal resistance.

- Push it manually as hard as possible.

- Observe if the filament flowing through the nozzle (if the obstruction is total, it may non extrude anything).

- Permit the printer cool downward to around 90°C for PLA and 160°C for ABS. Continue the pressure during cooling.

- When the printer reaches the lowest temperature mentioned in footstep 5, remove the filament quickly and forcefully from the hotend and inspect the semi-fused part of the filament. This must have a piddling bit of dirt (blackness spots). Those black spots were causing the blockage.

- Cut the dingy part of the filament and repeat from step 2 until the filament comes out clean.

Using this method is a great way of removing nigh of the dirt and dust that may take gotten inside of the nozzle, which you might take not been able to remove using the needle method.

But be certain to non damage the printer when pulling from the filament, since you may need to put in a fiddling extra forcefulness to become it out.

Use a Cleaning Filament

There are a couple filament brands out there that sell a "Nozzle Cleaning Filament" that works surprisingly well.

To utilize it but load information technology into your printer like you would with any regular filament (with Direct drive printers). If your printer uses a Bowden setup, and so it's advisable to remove the Bowden tube first and to manually feed the filament into the hotend.

How to clean the nozzle using cleaning filament:

- Preheat the nozzle to the temperature required for the cleaning filament (usually 230°C).

- Push button the cleaning filament all the way in until a little comes out through the nozzle and then only permit information technology sit there "cooking" for a couple minutes.

- Once 5 minutes have passed, feed a piddling more filament into the nozzle and wait again.

- Echo this process a couple of times.

- Remove the cleaning filament and load regular filament into the printer.

- Extrude some filament to check if it's coming out properly.

This method works surprisingly well and I recommend information technology to anyone who merely wants to allow the printer clean the nozzle by itself and who doesn't want to have to become through the process of doing a couple cold pulls or inserting a needle into the nozzle.

Unclog/clean the nozzle outside of the printer

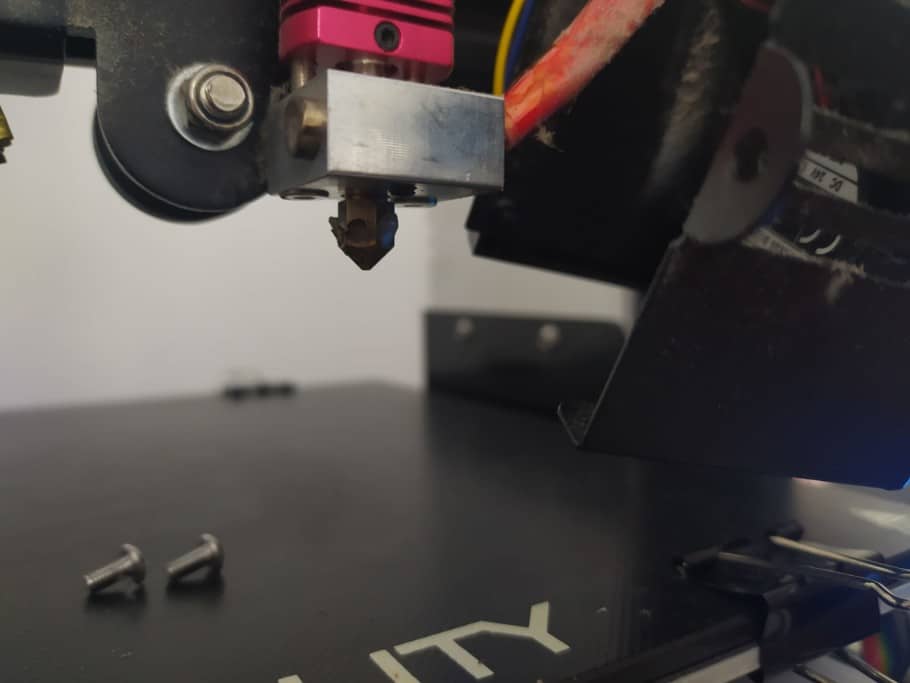

All of the methods I but described are done with the nozzle nonetheless installed on the printer, just sometimes it's not plenty and you have to remove the nozzle to really "go in there" and clean it thoroughly.

If you never removed the nozzle on your 3D printer, it's non that hard to do. However, always, and I hateful Always, preheat the nozzle before unscrewing it equally well every bit when you're screwing it back in (you lot can spiral it in common cold but don't tighten it. Do the final tightening after heating it up), otherwise you lot may damage the hotend.

Now, I would recommend doing a couple cold pulls before unscrewing the nozzle to remove equally much material as possible first. Once you remove the nozzle yous accept two options; remove the gunk mechanically or using solvents.

Make clean the nozzle using solvents (ABS, PLA)

Depending on the filament that acquired the clog, you can use different kinds of solvents to remove said clog from the nozzle. All the same, you will showtime need to completely remove the nozzle from the printer. Just remember to preheat the printer before removing information technology.

How to unclog a nozzle using solvents:

- Remove the nozzle from the printer and identify it into a vat or bowl of the following solvents for a couple of hours: Ethyl Acetate for PLA and Acetone for ABS.

- If you were using some other filament, check what solvent works for information technology and place the nozzle inside of information technology for a couple hours.

- Take the nozzle out of the solvent and use pliers, needles, and other pointy objects to remove the remainder of the filament and dirt particles.

Clean the nozzle mechanically

While this may probably be the best method of all, you lot will demand a heat gun or some other way of seriously heating up the nozzle to a indicate where the plastic inside of it softens a little, some long nose pliers and the aforementioned needles I mentioned before (the ones that mostly come up included with the printer), so continue that in mind.

How to clean the nozzle using the heat gun:

- Set the heat gun to low and place information technology on your working surface (desk) facing upwards.

- Using pliers, place the nozzle directly into the estrus until it's heated up.

- Apply the needle and the long olfactory organ pliers to remove equally much of the contaminants equally possible.

Go through this process until yous tin run into that the nozzle is now clean (look straight through information technology and if you can see that the opening is perfectly round, you should be good to get).

Note: Be careful with hardened nozzles, however, since overheating them may cause them to lose their hardened backdrop and may get damaged.

How to prevent the nozzle from clogging up

While information technology may not be that difficult to clean a nozzle, preventing information technology from happening is much smarter than but dealing with it in one case information technology happens.

Hither are some recommendations on how to avoid nozzle clogs which are actually easy to implement:

Keep the printer in a make clean environment

Since dirt & grit buildup can cause the nozzle to clog, keeping the printer in a room that is clean and where at that place isn't as much dust flying around will help prevent those dust buildups over time.

This is considering dust will adhere to the filament, which will and so exist pushed into the nozzle by the extruder and all those dust particles will "cook" and burn inside of the nozzle causing it to clog over time.

Of course, there is a solution to this problem and it's most gratis.

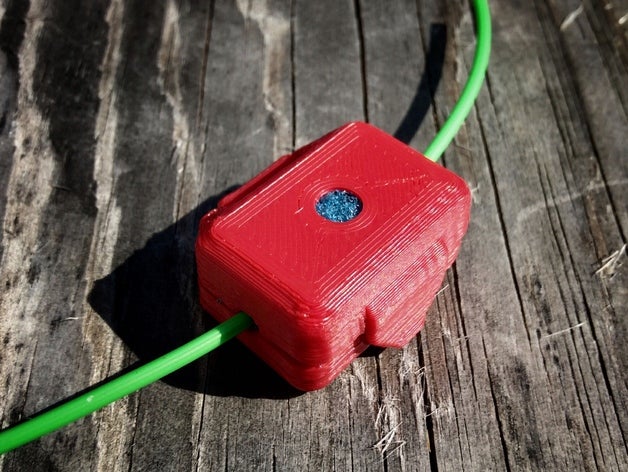

Use a filament dust filter

Filament dust filters are just that; a filter that goes around the filament and removes all the grit before it enters the hotend or the Bowden tube.

The are enough of designs online that you lot can download for costless and print, but you don't even demand to practise that since you can simply cutting off a little piece of a regular kitchen sponge and stick the filament through it.

Now every time the extruder pulls on the filament, it has to go through that piece of sponge and all the dirt and dust will be wiped off.

Use quality filament

Like I mentioned earlier, non all filament is made equal and not al manufacturers have the aforementioned strict quality-control and some filaments may come out with a larger tolerance (with a bore that varies more than information technology should), or with foreign particles in it that may crusade clogs over time.

Essentially, don't buy the cheapest filament you lot can observe simply because information technology's affordable. Read reviews and opinions about it before you decide to purchase.

The brands that I generally use are SUNLU or Hatchbox, which are all quite affordable and I never had a problem with any of them.

Don't preheat indefinitely

Preheating the nozzle for long periods of time means that the filament gets to sit inside of the nozzle and "cook" for much longer than it's supposed to, and even though it might start to ooze, over fourth dimension information technology'due south going to get-go melting further up, similar to what happens with "estrus creep", and cause a blockage.

Mostly speaking, you should preheat the printer and offset a print as soon as it reaches the desired temperature. Leaving it preheating for 30 minutes could crusade some problems.

Conclusion

If y'all notice that filament is starting to get stuck to the nozzle and the heatblock, utilise a brass brush (or steel, if the nozzle is made out of steel) to remove it. Merely call up to preheat the nozzle start.

This will continue said plastic from sticking to the print and ripping it off the build plate.

Too, if your heatblock & nozzle don't have a silicon boot, brand sure to get one and install information technology since it will help a lot!

If you're dealing with a chock-full nozzle, and then I'd recommend going through the steps in the society I listed them, since you may want to try cleaning the nozzle while it's withal attached to the printer first for practicality reasons.

If that doesn't work, and so unscrew the nozzle Afterward PREHEATING Information technology and go through the rest of the steps.

I promise this data was useful!

Take a nice day!

Source: https://3dsolved.com/ender-3-clean-the-nozzle-unclog-it/

Posted by: johnsonbigod2001.blogspot.com

0 Response to "How To Clean A Clogged Nozzle.on An Ender 3"

Post a Comment